Professional Analysis: Dye-Sublimation Printing Technology

December 9th 2024

Definition

Dye-sublimation represents a breakthrough in modern printing technology. Unlike traditional methods where ink remains on the material surface, this technology employs a unique molecular penetration process that embeds ink directly into the substrate's internal structure. Initially widely adopted in commercial displays, particularly for large-format fabric printing in trade show exhibits, it has now expanded into numerous other applications.

Workflow

The dye-sublimation printing process follows these key steps:

- Print design on transfer paper using specialized sublimation ink

- Allow the ink to dry completely

- Position the transfer paper precisely on the target material (typically polyester fabric)

- Place both materials into a heat press

- Under high temperature, the ink transforms into gas

- The gaseous ink penetrates the fabric's fiber pores, forming chemical bonds

- Remove the printed material and discard transfer paper

- Cool to reveal a vibrant, durable print

Outstanding Advantages

Dye-sublimation printing holds a unique position in contemporary printing, distinguished by several superior characteristics:

Durability

The printed patterns flex naturally with the fabric without cracking, as the ink penetrates the fibers and forms chemical bonds, becoming an integral part of the fabric structure. This makes it ideal for sportswear and frequently stretched display materials.

Color Performance

The technology demonstrates exceptional color capabilities, offering unlimited color options and remarkable fade resistance. Even under intense light exposure, prints maintain their vibrancy due to the molecular-level bonding between ink and fiber.

Practical Benefits

Products show excellent water and sweat resistance. Since the ink integrates into the material rather than sitting on the surface, there's no risk of peeling or bleeding when exposed to moisture. Most items can be machine washed without compromising print quality - a crucial feature for apparel and home textiles.

Comparison with Other Printing Technologies

When compared to traditional methods like heat transfer printing, dye-sublimation offers distinct advantages:

Heat transfer printing applies ink to the material surface through heat pressure, creating a coating. While this method offers simple operation and low initial costs, suitable for small-batch personalization, it has significant limitations:

- Surface ink prone to cracking and peeling

- Limited water resistance and durability

- Often produces an artificial glossy finish

In contrast, dye-sublimation's molecular bonding approach offers:

- Natural fabric feel without surface coating

- Superior wear and water resistance

- Finer color transitions and sharper image quality

- Better production efficiency for large batches

- Reduced waste and improved environmental performance

- Excellent digital integration for on-demand and customized printing

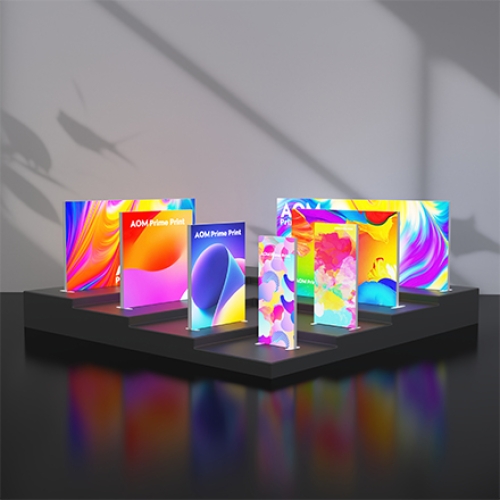

Exhibition Applications

Dye-sublimation printing proves particularly valuable in exhibition settings:

Display Solutions

- High-resolution corporate branding walls

AOM 15x8ft Custom Flat & Lightweight Tension Fabric Backwall Display

-

Vibrant banners and flags with saturated colors

- Decorative elements including table covers and ceiling fabrics

Marketing Materials

- Detailed product displays

-

Professional staff uniforms

- Custom fabric promotional items

Technical Benefits

- Exceptional color accuracy

- Long-term durability

- Environmentally friendly

- Reusable materials

Implementation Guidelines

Successful implementation of dye-sublimation printing for exhibitions requires careful attention to several key aspects. The process begins with comprehensive color calibration testing to ensure accurate brand color representation, followed by careful material selection based on specific display requirements and environmental conditions. Lighting considerations are crucial, as exhibition venues can vary significantly in their lighting setups, requiring careful adjustment of print parameters to achieve optimal visibility and impact. Additionally, understanding and complying with venue requirements, including mounting restrictions and safety regulations, ensures smooth installation while maintaining visual effectiveness. These carefully planned steps help create impressive displays that meet both aesthetic and practical requirements while maximizing the benefits of dye-sublimation technology.

Dye-sublimation printing provides versatile visual solutions for exhibitions, enhancing booth impact and brand presentation. It delivers high-resolution graphics with brilliant color vibrancy, offering easy storage and reusability across multiple events, helping exhibits stand out in competitive environments.

AOM's fabrics exclusively feature dye-sublimation printing technology, delivering stunning high-resolution graphics with exceptional color vibrancy that will make your booth stand out from the competition. These durable fabrics maintain their quality over time and can be reused multiple times, making them the best choice for maximizing your return on investment. If you have any questions, please contact us.

.jpg)

.jpg)

.jpg)